Researchers at Sandia National Laboratories have been expanding their severe accident computer modeling program, called Melcor, to work with different reactor geometries, fuel types and coolant systems. This work is intended to assist the U.S. Nuclear Regulatory Commission (NRC) to evaluate the safety of the next generation of commercial nuclear power reactors, fuel cycle facilities and fuel technologies.

Sandia and the NRC have collaborated for decades to advance the understanding of system performance under accident conditions. This research has covered areas such as accident progression, combustible gas generation and transport, molten core concrete interaction, fuel coolant interactions and many other subjects of interest.

The Methods for Estimation of Leakages and Consequences of Releases (Melcor) simulation program can model a wide variety of phenomena including severe accidents that can occur at a nuclear power plant. Melcor can estimate the extent of radioactive material release possible due to the accident. Work on Melcor began following the Three Mile Island accident in 1979.

Since the turn of the century, Melcor has been expanded and updated to support safety assessments for other kinds of nuclear facilities including research reactors, reactors that produce medical isotopes and U.S. Department of Energy facilities that work with radioactive materials. Even fusion reactors can be modeled with the program.

The computer program is used to inform the NRC’s regulator decision-making including licensing reviews for new reactors, regarding the risks from very low-likelihood but high-impact accidents. Sandia’s program was used to study the nuclear disaster in Japan’s Fukushima nuclear power plant in 2011. It has also evaluated the risk-reduction potential of several safety improvements to U.S. nuclear reactors for the NRC.

Since 2018, Sandia has expanded Melcor to enable the evaluation of the risks of next-generation reactors and impacts to the fuel cycle in general.

Larry Humphries is the lead Melcor developer. He said, “We want to leverage the decades of experience and validated models in the code and extend it to new reactor designs and new applications. This code is an ideal tool to apply to new reactor designs where there is a great deal of uncertainty. It has the ability to set sensitivity parameters and determine which variables are critical to produce risk assessment data for regulators.”

In order to demonstrate that Melcor is ready to assist the NRC in reviewing new reactor designs, the team developed models of three published nuclear reactor designs. The three reactor designs were chosen because they represented the diversity of next generation reactors including a microreactor originally designed by the Los Alamos National Laboratory, a high-temperature helium-cooled reactor and a high-temperature molten- fluoride- cooled reactor.

The reactor models include everything from the radionuclides expected to be in the reactor vessel and the building that surrounds it to the coolant pipes and the physical properties of the fluids in the pipes. Melcor analyzed what happens as time progresses to see how much, if any, fission products are released.

The improvements and enhancements to Melcor have been demonstrated at several recent virtual public meetings. The reason for those meeting was to illustrate for U.S. policy makers, members of the nuclear energy industry, international nuclear energy regulators and members of public interest group that the NRC has the computational tools needed to evaluate the safety of new and advanced reactor designs.

David Luxat is the manager for Sandia’s nuclear reactor severe accident modeling group. He said, “The code is a repository of decades of knowledge on nuclear accidents, which shows nuclear energy is fundamentally low-risk for society,” said David Luxat, manager for Sandia’s nuclear reactor severe accident modeling group. “We have been able to leverage this knowledge to enhance the safety and economics of nuclear power plants in the US. Now, Sandia is working to expand on and apply this knowledge to enable the next generation of even safer, more economic nuclear power reactors. This will be critical to combatting climate change and enhancing the energy security of future generations.”

Brad Beeny is a Sandia nuclear engineer and Melcor code developer. He said, “If industry is ever going to be able to build anything new and exciting, we need to be able to do safety and licensing calculations of the next generation designs so that the US regulators can assess them. We’re mostly concerned with characterizing the radiological hazard that could be posed to the public, should an accident happen. It may not be the most flashy aspect of nuclear energy, but it is one of the most necessary.”

Blog

-

Nuclear Reactors 940 – Sandia National Laboratory Enhances Its Melcor Nuclear Risk Monitoring Software For The NRC

-

Nuclear News Roundup Aug 27, 2021

US scientists working to solve Heisenberg cube mystery world-nuclear-news.org

The NDB Technology team behind the battery that could allegedly last up to 28,000 years spoke to ELN about the new application of their technology energylivenews.com

Nuclear energy is anything but clean theguardian.com

New transport casks delivered to KHNP world-nuclear-news.org

-

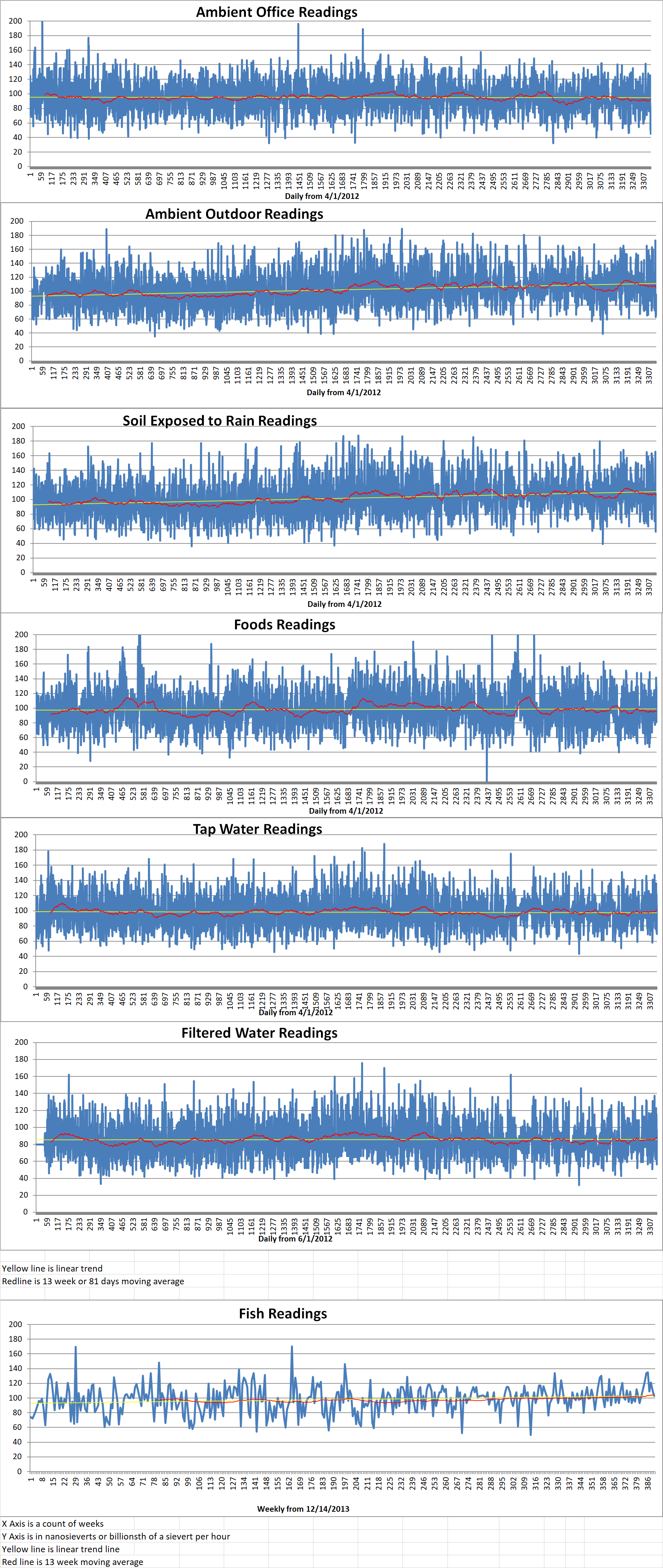

Geiger Readings for Aug 27, 2021

Ambient office = 45 nanosieverts per hour

Ambient outside = 66 nanosieverts per hour

Soil exposed to rain water = 69 nanosieverts per hour

Red bell pepper from Central Market = 128 nanosieverts per hour

Tap water = 107 nanosieverts per hour

Filter water = 96 nanosieverts per hour

-

Radioactive Waste 816 – Bechtel Making Progress On Completing The Vitrification Plant At Hanford – Part 3 of 3 Parts

Part 3 of 3 Parts (Please read Part 1 and Part 2 first)

During the retrieval of radioactive waste from the tanks, workers have to operate retrieval equipment inserted through relatively small openings in the top of the tank from a nearby control trailer. They use pressurized water to dissolve the solid or salt-cake waste and flush it to the pump that transfers the waste to a double-walled tank.

Peggy Hamilton is the retrievals manager for WRPS. She said, “It takes a particular combination of water and pressure to create a slurry, which suspends the heavier solids in a liquid that can be pumped out and sent via transfer lines to another tank. We use lessons we learned and technologies developed during the successful retrieval of waste from other tanks to help us complete this challenging work.”

Tank AX-103 is the third million-gallon tank to have its radioactive waste removed in a group of four tanks referred to collectively as the AX Tank farm. WRPS has already retrieved waste from tanks AX-102 and AX-104. Retrieval from the last tank, AX-101 is scheduled to begin next year.

Preparing a decades old tank farm for the safe retrieval of radioactive wastes takes years of planning a retrofitting. Hanford workers remove old, contaminated equipment from the tank in order to make space for the equipment needed to retrieve the waste. Then they install modern retrieval equipment, ventilation safety and leak-detection systems and transfer lines to transfer the waste to a double-walled tank.

To date, workers have completed retrieving the waste for seventeen of Hanford’s one hundred and forty-nine older single walled tanks. After tanks AX-102 and 104 go through a standard technical review for completion that can take several months, the list of retrieved tanks will grow to nineteen. Hanford’s single-walled tanks were constructed of carbon steel and reinforced concrete between 1943 and 1964 to store radioactive and chemical waste created during the production of plutonium in World Was II and the Cold War era.

For a long time at Hanford, there was little concern for the environmental damage caused by weapons production. Millions of gallons of highly toxic chemical and radioactive waste were simply poured out on the ground and allowed to sink into the soil. Some of this waste eventually wound up leaching out and contaminating the Columbia River. A great deal of work has been put into preventing this in the future.

When the waste was put into single-walled tanks, poor records were kept with respect to what was being put into each tank. Different blends of toxic chemicals and radioactive materials with different particle sizes and viscosities were stored in different tanks. The tanks were intended to last until the waste could be vitrified. Unfortunately, some of the single-walled tanks began to leak. This led to the construction of double-walled tanks which received waste from leaking tanks. Then, in time, some of the double wall tanks began to leak.

The state of Washington and the U.S. DoE have been involved in legal battle for years over the lack of progress in cleaning up Hanford. The completion of the vitrification plant is way behind schedule and way over budget. Maybe the cleanup program can now move forward more swiftly. -

Nuclear News Roundup Aug 26, 2021

Japan seeks support for Fukushima nuclear water release federalnewsnetwork.com

Argentina reveals its nuclear new build plans world-nuclear-news.org

Putin launches construction of new nuclear subs and warships defensenews.com

Foundation set in place for BREST reactor world-nuclear-news.org

-

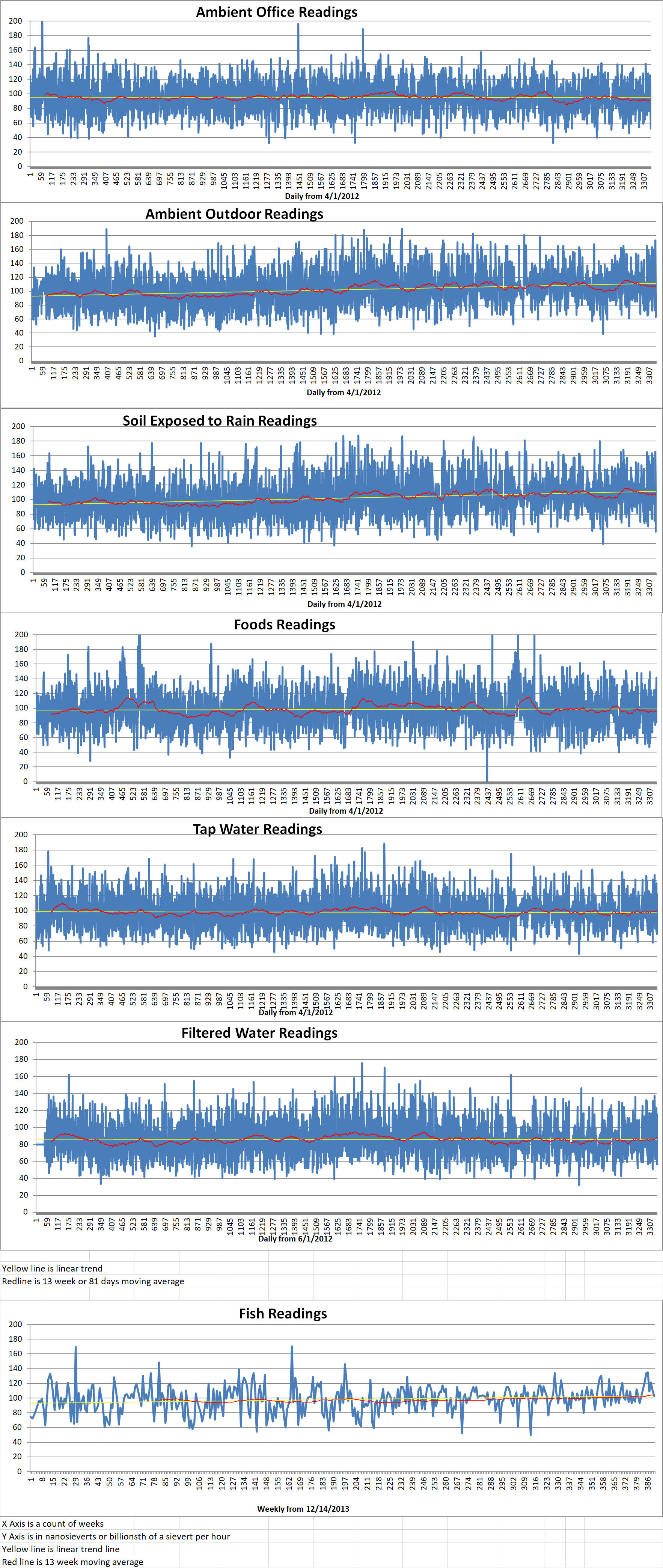

Geiger Readings for Aug 26, 2021

Ambient office = 52 nanosieverts per hour

Ambient outside = 95 nanosieverts per hour

Soil exposed to rain water = 108 nanosieverts per hour

Avocado from Central Market = 89 nanosieverts per hour

Tap water = 94 nanosieverts per hour

Filter water = 87 nanosieverts per hour

-

Radioactive Waste 815 – Bechtel Making Progress On Completing The Vitrification Plant At Hanford – Part 2 of 3 Parts

Part 2 of 3 Parts (please read Part 1 first)

Local contractor Two Rivers Terminal (TRT) made its first delivery of materials that will be used to immobilize waste stored in the underground tank in glass logs. EM Office of River Protection (ORP) prime contractor Bechtel National awarded a contract to Two Rivers Terminal of Pasco, Washington. The contract appoints TRT to source, import, store and deliver materials that will be utilized in the glass forming vitrification process. This activity is part of the Direct-Feed Low-Activity Waste (DFLAW) program.

The DFLAW program is a system of interdependent projects and infrastructure improvements, managed and highly integrated, that must operate synchronously to vitrify the radioactive waste. During the process of vitrification, the contaminated waste and glass-forming materials are mixed together and heated to over two-thousand-degree Fahrenheit inside one of the two large melters in the Low-Activity Waste Facility. Following melting, the mixture is poured into stainless steel containers for safe storage.

The first delivery of glass-forming materials was lithium carbonate which is an industrial chemical used in processes such as manufacturing lithium-ion batteries. Other materials that will be used in vitrification are varied, consisting of multiple silicate compounds and other chemicals. Sucrose, better known as common sugar, is on the list of the ingredients. Silica will be the primary compound used in the vitrification process. The initial materials delivered to the WTP will be used in the process of starting up and tuning the first of the two melters later this year.

TRT intends to source the glass-forming materials both domestically and internationally. About half of the needed materials will be coming from locations around the U.S. The contractor will be required by contract to maintain a three-months supply of materials. Before delivering the vitrification materials to the WTP, TRT will work with another business called Mukang Labs which is also located in Pasco in order to ensure that the materials meet the quality specification in the contract for vitrification. Mukang Labs will take samples and analyze the materials. The results will be reported to Bechtel. TRT is a fertilizer and chemical formulator, distributor and importer that serves agricultural and industrial businesses in south central Washington state.

EM said that on the 17th of August ORP tank operations contractor WRPS had recently begun retrieving radioactive and chemical was from another massive underground tank at the Hanford Site. Over the next several months, workers will retrieve approximately one hundred thousand gallons of solid and sludge-like materials for vitrification or immobilization in glass.

Ricky Bang is the Hanford EM Tank Farms Program division director. He said, “Moving waste from older single-shell tanks to newer double-shell tanks is an important step in progressing our risk-reduction mission,” said Ricky Bang, Hanford EM Tank Farms Program division director. “It’s not easy to access the tanks or move this kind of waste, and it takes specialized tools and techniques that have been developed, tested, and proved successful to meet this challenge.”

Please read Part 3 next -

Nuclear News Roundup Aug 25, 2021

Most Germans reject nuclear power as sustainable investment target – survey cleanenergywire.org

Kinzinger asks Biden to keep Byron nuclear station open centralillinoisproud.com

Authorities issued a warning Monday that airspace over U.S. Los Alamos National Laboratory is off limits to drones defensenews.com

Finland’s Olkiluoto 3 nuclear reactor faces another delay reuters.com

-

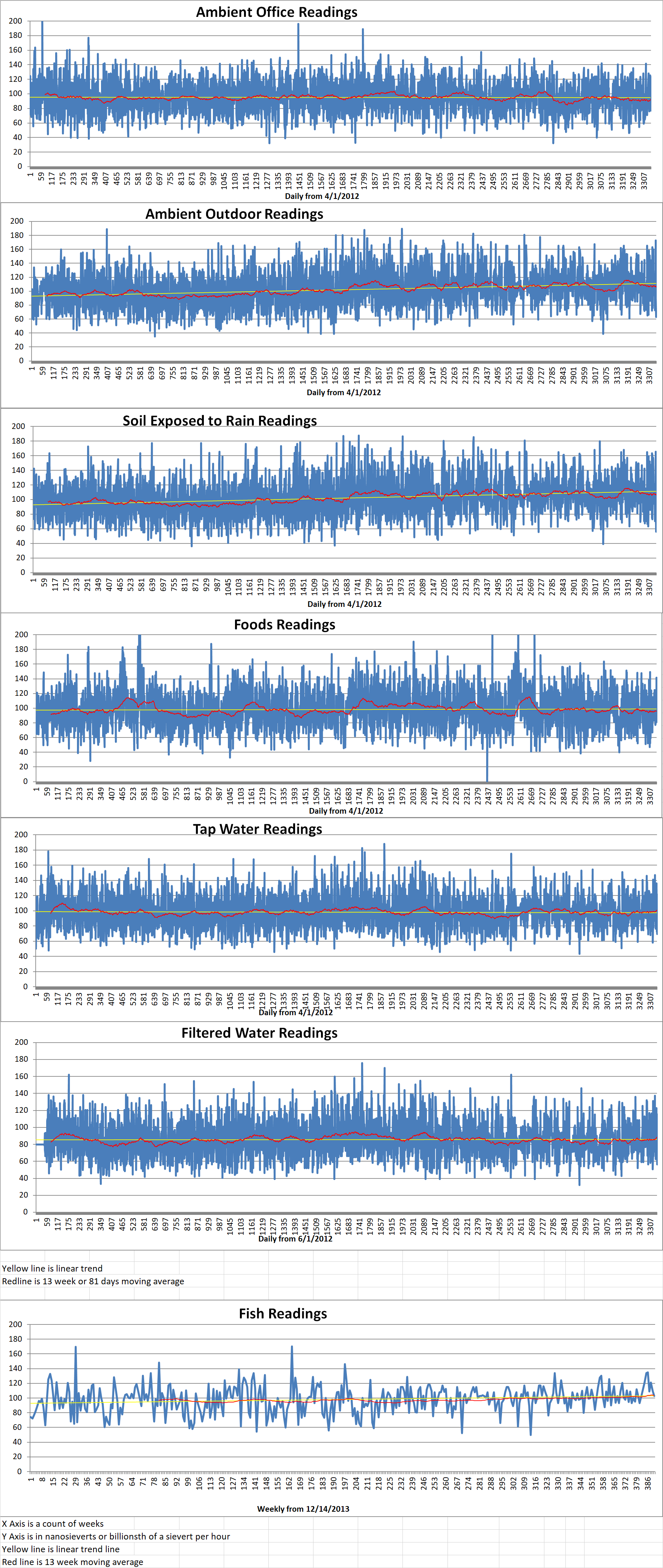

Geiger Readings for Aug 25, 2021

Ambient office = 77 nanosieverts per hour

Ambient outside = 70 nanosieverts per hour

Soil exposed to rain water = 74 nanosieverts per hour

Roma tomato from Central Market = 81 nanosieverts per hour

Tap water = 70 nanosieverts per hour

Filter water = 56 nanosieverts per hour

-

Radioactive Waste 814 – Bechtel Making Progress On Completing The Vitrification Plant At Hanford – Part 1 of 3 Parts

Part 1 of 3 Parts

The U.S. Department of Energy (DoE) Office of Environmental Management (EM) has announced that tank operations contractor Washington River Protection Solutions (WRPS) has finished construction of a pipeline that will transfer waste from Hanford’s buried waste tanks to the Waste Treatment and Immobilization Plant (WTP) for vitrification, also known as immobilization in glass.

The Hanford Nuclear Reservation was established during World War II to manufacture nuclear weapons. It is the most radioactively contaminated site in the U.S. and is the subject of a decade’s long multibillion dollar clean-up effort. Massive underground storage tanks that range in capacity from fifty-five thousand gallons to over one million gallons were constructed at Hanford to hold wastes from the production of plutonium. They are located in eighteen “tank farms” which each hold from two to sixteen tanks.

Brian Vance is the manager of the Office of River Protection and Richland Operations Office. He said, “This is a significant step forward in our Direct-Feed Low-Activity Waste Program to treat tank waste. The connection represents another example of this year’s progress and also demonstrates the strong commitment by the Department of Energy and our contractors to safely move our important site mission forward.”

The new thirty-five-hundred-foot pipe inside a pipe transfer line connects the WTP to a double-walled tank in the AX tank farm. This tank will serve as a holding tank for liquid waste that has been treated by the Tank-Side Cesium Removal system next to the AX tank farm to removed radioactive cesium and solids. Hanford workers installed the cesium removal system next to the AX Tank Farm earlier this year and are currently conducting readiness reviews before starting to treat tank waste early next year.

John Eschenberg is the WRPS president and CEO. He said, “For the first time, tank farms are connected to the Vit Plant, providing the avenue for transferring treated tank waste to the plant for vitrification. It’s exciting to be a part of putting the infrastructure in place to facilitate this critical mission.”

During the hot commissioning and operation at the WTP, the treated waste will be pumped in batches from the double-walled tank directly to the WTP for vitrification and disposal.

Valerie McCain is the WTP project director and senior vice president for Bechtel National Inc., the contractor designing, building, and commissioning the plant. She said, “It’s exciting to see the physical connection from the tank farms to the Vit Plant. This final tie-in symbolizes the collaborative spirit at Hanford and how we are all committed to treating waste.”

Initial work at the WTP had to be halted because of problems caused by vibration in the piping system due to different sizes of particles in the waste from the tanks.

Bechtel expects to heat up the first of two vitrification melters in the Low-Activity Waste Facility by the end of 2021 as part of the plant commissioning process. Hanford is preparing to start vitrifying tank waste by the end of 2023 if everything goes according to plan.

Please read Part 2 next