When enriched uranium is used in nuclear reactors, the exhausted fuel consists mainly of U-238 with small amounts of U-235, plutonium and minor actinides such as neptunium, americium, curium, berkelium, californium, einsteinium, and fermium. There are commercial facilities in France, the United Kingdom and Japan for reprocessing spent fuel. Reprocessing is also carried out at nuclear weapons facilities. Reprocessing is currently carried out in eleven countries.

Originally, spent fuel was reprocessed primarily for the purpose of extracting plutonium for use in nuclear weapons. With the spread of commercial reactors, plutonium began to be used in Mixed Oxide (MOX) reactors.

CANDU reactors are designed to use natural uranium as a fuel so spent fuel can be used in these reactors because the U-235 remaining is still present in a higher ratio than naturally occurring uranium. It only needs to be processed physically in order to be utilized with no chemical processing required.

Reprocessed uranium and depleted uranium can be used in fast breeder reactor blankets but there is currently no commercial market for this use. Currently the price of uranium is too low to justify re-enrichment of spent fuel to supply commercial reactors but that could change if the price of uranium continues to rise.

The current main method of reprocessing is Plutonium and Uranium Recovery by Extraction (PUREX). The spent fuel is dissolved in nitric acid and the resulting liquid is filtered. Organic solvents are used to created compounds of plutonium and uranium which are then chemically separated and extracted. A modified version of PUREX known as UREX just extracts the uranium which constitutes most of the spent fuel. TRUEX is another extraction technique which removes the americium and californium and lowers the alpha radioactivity of the spent fuel making disposal easier.

A number of obsolete chemical processing methods have been abandoned in favor of the processes listed above. Possible new industrial processes have been developed in the laboratory and additional theoretical methods have been proposed including an electrochemical/ion exchange method , a high temperature pyrprocessing method that utilizes molten salts and molten metals, electrolysis and other new techniques.

Reprocessing is a dirty dangerous process. The spent fuel must be pulverized behind heavy shielding with protection against dust. When boiled in nitric acid, radioactive gases are generated. After the plutonium and uranium have been extracted, toxic radioactive liquids are left behind which must eventually be solidified for disposal.

Reprocessing can reduce the volume of waste but does not reduce radioactivity. Studies of the cost of a fuel cycle with reprocessing versus single use with waste disposal have been conducted but are not definitive because it is not possible to exactly define what the costs of disposal will be. There has been controversy surrounding reprocessing because of possible contributions to nuclear weapon proliferation, vulnerability to terrorism, political problems that arise when attempting to site a reprocessing plant.

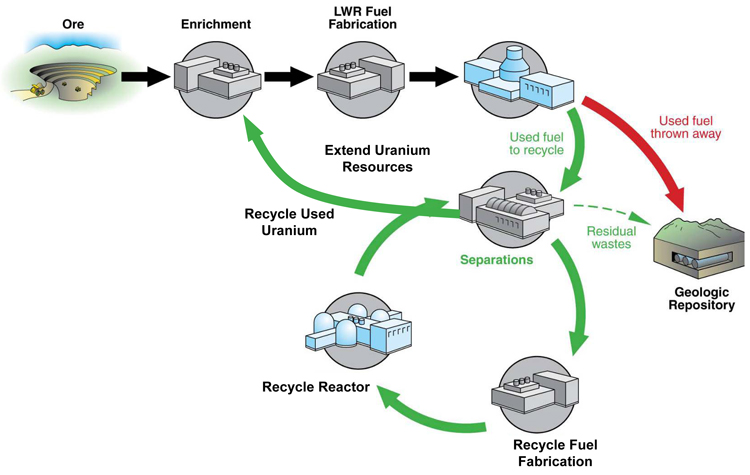

Closing the nuclear fuel cycle – from Argonne National Laboratory: